Product Description

Detecting Misalignment in a Vehicle’s Structure

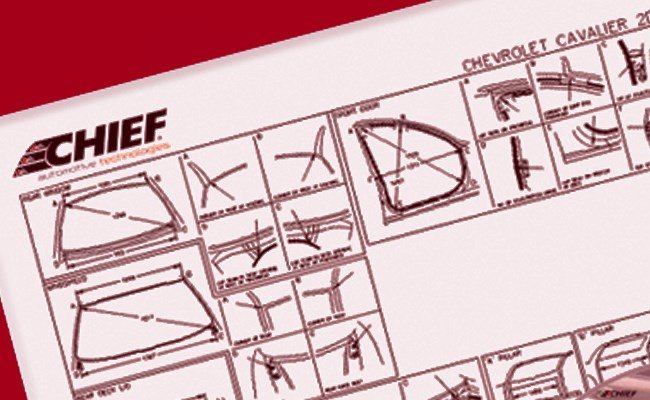

Whether detecting misalignment in a vehicle’s structure or verifying repairs has eliminated the damage, the TrueScan computerized measuring system can do the job. TrueScan integrates the precision of laser scanning with a computerized database for unmatched accuracy in collision repair and analysis. In addition to showing the extent of collision damage, TrueScan monitors progress throughout the repair and verifies the vehicle’s structure is correctly aligned. Three separate reports verify the vehicle’s structural condition by showing overhead diagrams that display centerline, datum line, and datum height measurements, offering indisputable evidence that the repairs made were not only needed…but returned the vehicle frame to its pre-collision condition.

TrueScan™ System Measures on the Principle of Triangulation

The system’s single hub scanner houses Laser Lights that reflect off of revolving mirrors toward light-reflective Targets (each bearing a unique code) that are suspended from a vehicle’s reference points. The Body Scanner houses photo sensors that identify the angle of revolving laser reflections. This information is transferred to the computer which performs the triangulation and Target identification functions.

Using TrueScan™ is as simple as.

- Pull up detailed frame specifications for the vehicle being repaired

- Hang the attachments and targets as instructed by TrueScan™’s tutorial

- Position the Galileo™ scanner under the vehicle

- Watch as TrueScan™ shows you not only where the vehicle frame is out of alignment but also by how much and in what direction!

Professional Training

Chief Automotive Systems, Inc. also offers professional training. For maximum productivity and equipment utilization, each person operating a TrueScan computerized measuring system should receive training conducted by Chief Training Department personnel. Find out more information about Chief University.

Reviews

There are no reviews yet.